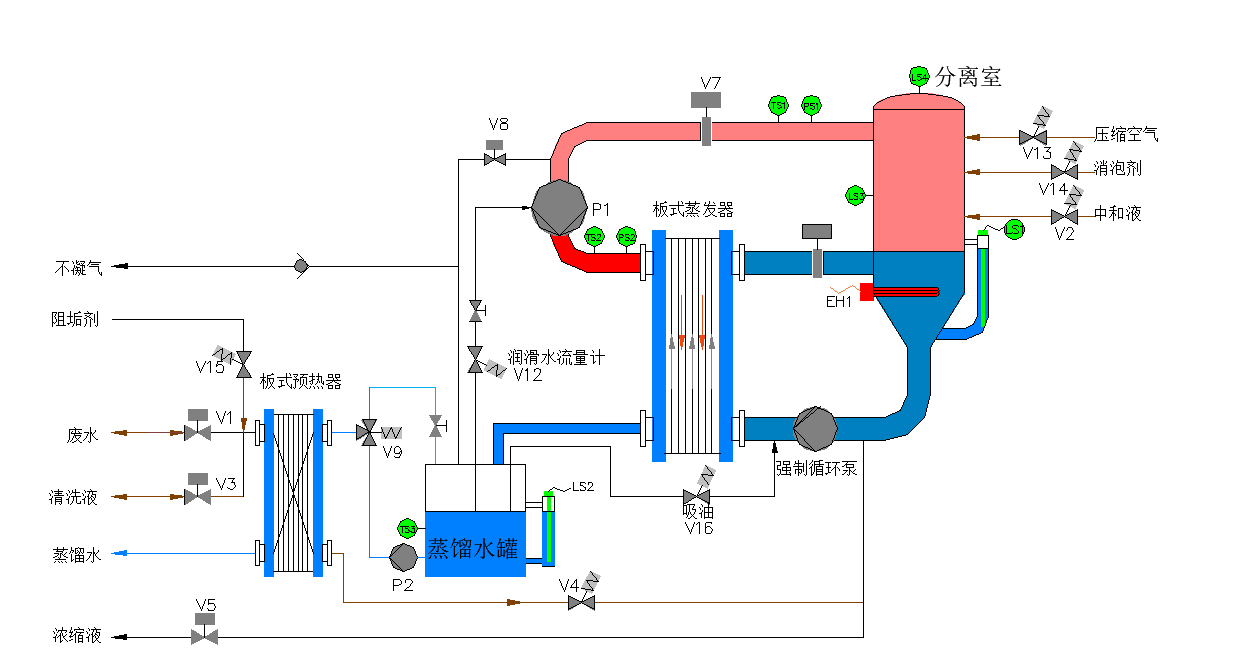

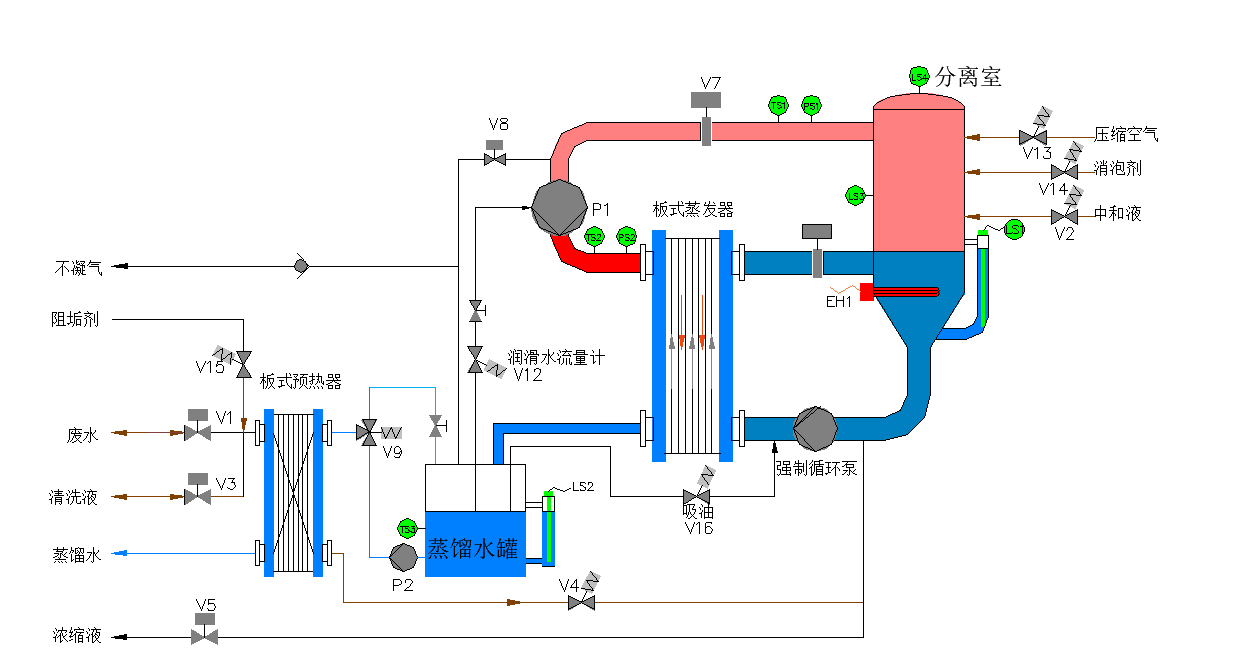

Working principle:

1. When the compressor starts, negative pressure forms in the tank, and sewage is automatically sucked into the evaporator;

2. Electric heating starts, the compressor operates at low frequencies, and the system enters heating mode;

3. Due to a negative pressure of 500mbar inside the tank, the sewage begins to boil when it is heated to 85 ℃, producing a large amount of water vapor;

4.85 ℃ steam is sucked in by the compressor and compressed into 100 ℃ steam;

Immediately heating the sewage inside the heat exchange plate with water vapor at a temperature of 5.100 ℃, it liquefies into condensate and is discharged in this cycle;

6. Due to the continuous discharge of condensate, the concentration of sewage inside the tank gradually increases and is ultimately discharged outside the tank.

Equipment processing capacity and size power:

| Processing capacity kg/h |

Installed power/kW |

External dimensions (mm) length * width * height |

Weight (Kg) |

Energy consumption per ton of water kW. h |

| 1000 |

110 |

3798 * 2068 * 3499 |

7500 |

50-80 |

| 1200 |

160 |

4151 * 2130 * 3491 |

7000 |

50-80 |

| 1500 |

185 |

4772 * 2130 * 3873 |

8500 |

50-80 |

| 1800 |

265 |

4800 * 2230 * 3910 |

9000 |

50-80 |

| 3000 |

360 |

5985 * 2600 * 4620 |

13000 |

50-80 |

| 3600 |

310 |

7900 * 2350 * 4800 |

14000 |

50-80 |

| 5000 |

445 |

10000 * 2800 * 6000 |

22000 |

50-80 |

| 7000 |

605 |

10230 * 2830 * 6120 |

23500 |

50-80 |

| 10000 |

615 |

14903 * 3000 * 9843 |

50000 |

50-80 |