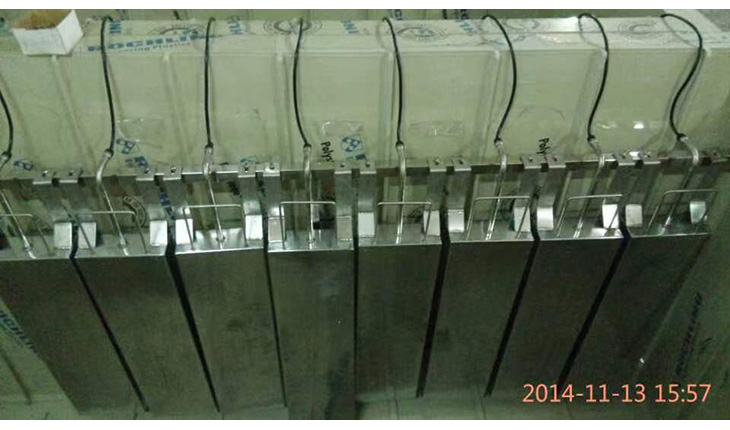

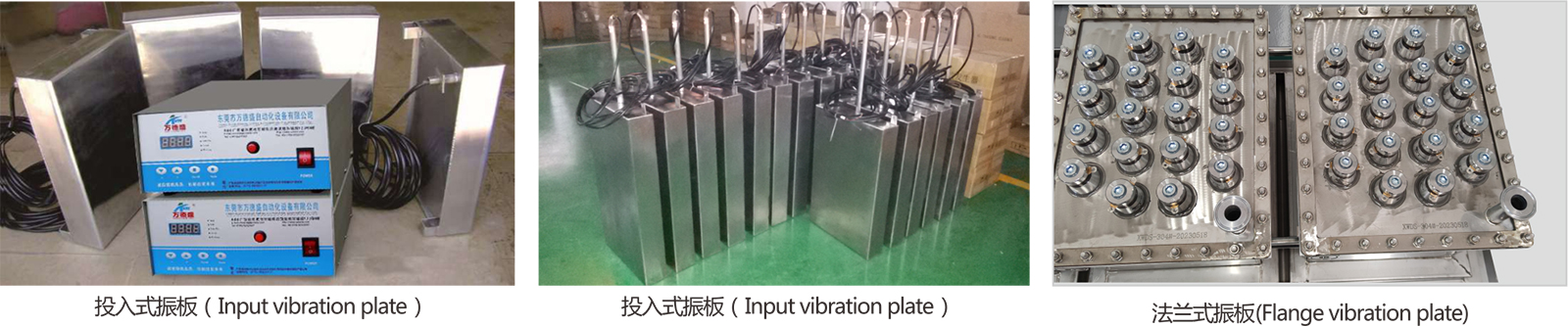

◆ Input type ultrasonic vibration plate can be inserted into the cleaning tank to form an ultrasonic cleaning system.

The flange type ultrasonic vibration plate is installed at the bottom of the cleaning tank and fixed with bolts to form an ultrasonic cleaning system.

Ultrasonic vibration plates are widely used and flexible, and can be applied to various cleaning combinations.

The working position can be divided into top vibration, edge vibration, and bottom vibration to achieve different cleaning effects.

The frequency can be selected as 28HKz, 40KHz, 80KHz, 100KHz, 120KHz and other ultrasonic frequencies.

◆ All stainless steel structure, acid and alkali resistant, beautiful and durable, made of titanium plate material for strong acid and alkali, reinforced and welded with encryption.

Thickened stainless steel welding with good sealing performance.

◆ Imported high Q-value oscillator with strong ultrasonic power and high electro-acoustic conversion efficiency.

The ultrasonic generator is connected to the vibrating plate in a split type, making maintenance and upkeep convenient.

◆ Can work continuously for 24 hours, suitable for large-scale production.